Super strong hulls

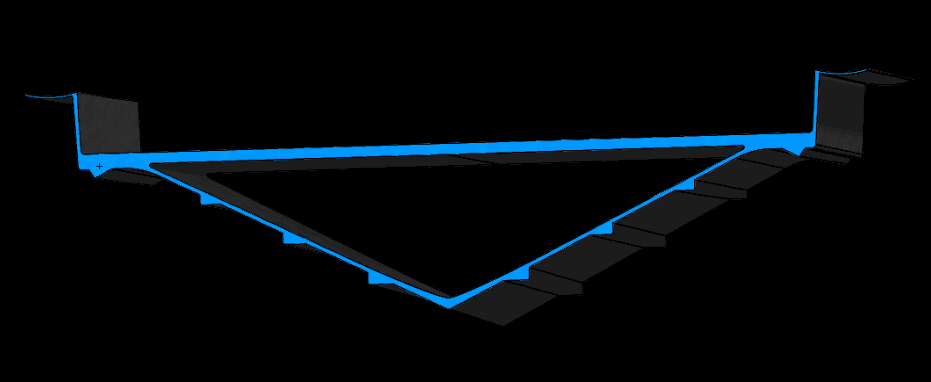

All Vorteq Ribs are high performing professional models. They are designed to be super strong and super efficient. Specialised hydrodynamic modelling optimises the hull form for maximum speed and maximum fuel efficiency.

Hulls are deep ‘V’ for a super soft, comfortable ride. Multiple spray rails aerate the water and minimise hull drag. Vorteq tunnel rails provide high directional stability and lift. Highly manoeuvrable and exciting to drive – nothing performs like a true Vorteq. See video.

Advanced construction

Vorteqs are built super tough and trouble free with the finest resins. Each stage of construction is subject to inspection and signed off only when it passes our strict quality control. Hulls are resin infused, and tri-axial glass reinforced. Polymer hull coring (in blue) reduces weight for increased strength and performance. This weight saving ethos makes launching and recovering quicker and easier. At sea the Vorteq is faster, more agile and great fun to drive.

High tech materials

Boat designs evolve over time, influenced by better materials and improved manufacturing techniques. With climate warming and the demise of fossil fuels power units need to be more eco friendly. With the use of high tech materials the Vorteq is both stronger and lighter.

This benefits both the environment and your running costs. This attention to detail is what makes the true Vorteq creatively different, and better.

Tough and long lasting

Vorteq inflatable tubes in Polyurethane are significantly tougher and longer lasting than those made Hypalon or PVC. This toughness is the secret to Vorteq’s smart looking appearance – even after years of hard service. Tested with an angle grinder a sample of PU was still performing 40 min later when a sample of Hypalon had worn through in 3 minutes (see photos).

PU

40mins with an angle grinder

Hypalon

3mins with an angle grinder

Streamlined welded seams

All seams on a Vorteq tube are computer controlled welded and then, thermally imaged inspected. This unique process guarantees the ultimate in seam strength and air tight sealing. Vorteq welded seams are over five times stronger than glued seams. A special double-edged laminar jointing system, invented and developed by Vorteq, streamlines the finished tube. There are no unsightly tapes to lift and snag (see photo).